Low-cost housing in India was seen for many years and has evolved much faster than any other technique in Civil Engineering. The engineering behind the low-cost housing earlier was to have a focus on the economic point of view but the facilities such as ventilation and leavable space were gone out of view.

|

| Old Form |

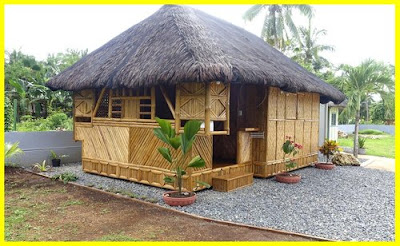

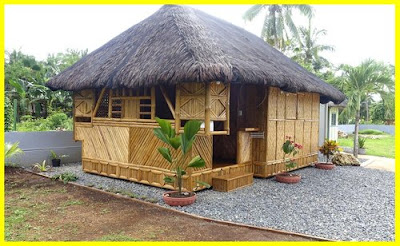

Then low-cost housing saw an architectural change that gave it a new loo and changes the was low-cost housing was seen, but an economic point of view was on the midway to increase and thus this was restricted. But later as the tech, machine, labor, and engineers were getting cheaper and came into huge numbers made the cost also low. This can be seen in many 1970s 1980s 1990s and 2000s where many states adopted new architecture and techniques to transform low-cost housing the way we looked it. Some eco-friendly ideas also came up where the climate is sunny most of the year can be used, but where rain and winters are prominent are not taken into consideration.

|

| Eco-friendly Housing |

Many states adopted a variety of plans and which showed the change check down:

As we know change is never-ending and the same is here, later in 2010 we can see that modular and prefabricated members are used made in factories and assembled on-site which help in finishing the work faster than the previous method, also reduced the transportation cost of concrete and reduce the workforce on-site and that helped in reducing the cost and made it more economic.

The next change which is definite is the use of 3D print in construction and which is proven by Larsen and Toubro, India (L&T India) to be used in low-cost housing where they show-cased a g+1 house which was created using 3D print construction tech and was successful. Soon this will change the construction industry and make it look like never before.

If you guys have any new technique which is evolving around you, mention it down below and share your thought too...

Comments

Post a Comment

Thank You for visiting, if you have any questions please feel free to ask: